Bolt Standards serve as the blueprint for selecting, manufacturing, and installing fasteners in everything from bridges to home appliances. These guidelines specify mechanical properties, dimensions, material composition, and environmental ratings, ensuring compatibility and safety across diverse applications. By mastering the fundamentals of Bolt Standards, engineers, contractors, and DIY enthusiasts can avoid failures, reduce rework, and streamline procurement. In this article, we’ll cover four essential facts you need to know to navigate the world of fastener specifications with confidence.

1. Standards Organizations Define Bolt Requirements

Bolt Standards originate from global and regional bodies that publish technical specifications to guarantee uniformity and reliability. Key organizations include:

- ISO (International Organization for Standardization)

- ASTM International (previously known as the American Society for Testing and Materials)

- DIN (Deutsches Institut für Normung)

- ANSI (American National Standards Institute)

Each body addresses specific aspects of fasteners, such as material grade, mechanical performance, thread geometry, and testing methods. Adhering to these recognized standards helps manufacturers certify that bolts meet minimum strength, ductility, and durability requirements.

Bolt Standards compliance is often mandatory in regulated industries like aerospace, automotive, and construction. Specifying the correct standard designation in procurement documents prevents mismatches, counterfeit parts, and costly project delays.

2. Material Grades and Strength Classes

Bolt Standards classify fasteners by material composition and tensile strength, enabling users to choose bolts that can withstand the forces in their application. In the United States, ASTM grouping and SAE grading are common, while metric systems rely on ISO classes. Typical designations include:

– ASTM A307 Grade A and B (low- to medium-strength carbon steel)

– SAE Grades 2, 5, and 8 (identified by radial markings on the head of the bolt)

– ISO Class 8.8, 10.9, and 12.9 (metric system indicating minimum tensile stress in megapascals)

Grade markings stamped on bolt heads—such as “8.8” or three radial lines—offer a quick way to verify strength class before installation. Choosing the correct class prevents overloading and ensures structural integrity under static and dynamic loads.

3. Thread Specifications and Tolerances

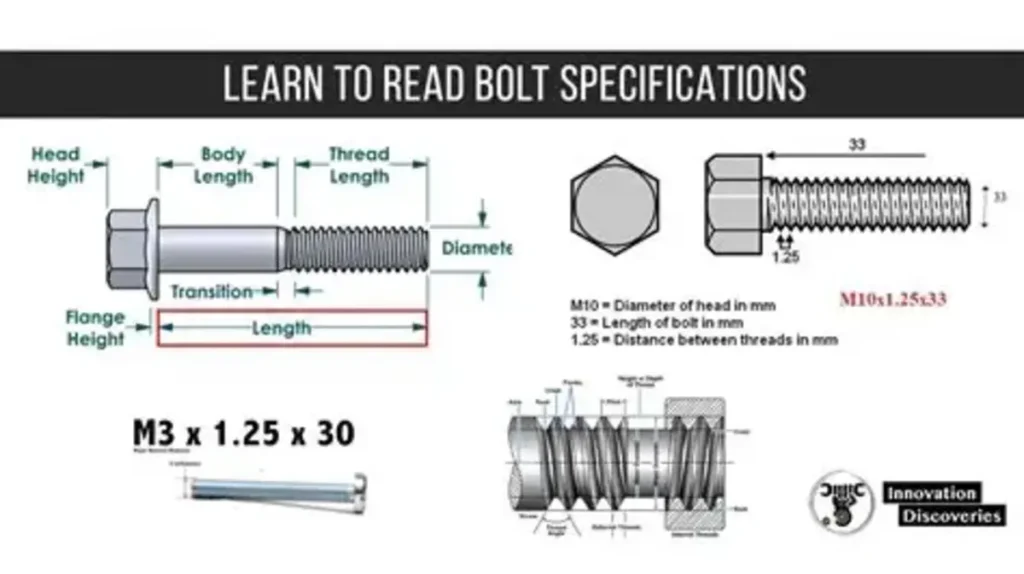

Bolt Standards also define thread geometry and tolerances to guarantee proper fit and load distribution. Key thread parameters include:

– Major diameter (refers to the widest part of the external thread)

– Pitch (the measurement between two consecutive thread crests)

– Thread form (Unified National, ISO metric, Acme, etc.)

Common thread series are coarse (e.g., UNC, ISO M coarse) and fine (e.g., UNF, ISO M fine), each offering trade-offs in strength, adjustment sensitivity, and resistance to vibration.

Beyond dimensions, Bolt Standards specify tolerance classes—like ISO’s 6g/6H for external/internal threads—to control the clearance or interference fit. Tight tolerances improve load transfer and reduce the risk of thread stripping in high-precision or high-pressure assemblies.

4. Surface Treatments and Environmental Ratings

Surface finishes significantly impact a bolt’s performance in corrosive, high-temperature, or wear-prone environments. Bolt Standards outline approved treatments, such as:

– Zinc plating or galvanizing for general corrosion protection

– Black oxide for mild rust resistance and aesthetic appeal

– Anodizing (for aluminum fasteners) to enhance hardness and corrosion resistance

– Cadmium or nickel plating in aerospace applications

Certain standards, like ASTM B633 for zinc coatings or ISO 4042 for electroplated coatings, define minimum thickness, adhesion, and salt-spray resistance. Specifying the right finish under the Bolt Standards framework extends service life and maintains safety margins, particularly in marine, chemical, or outdoor structures.

Conclusion

Baut tokohasil: Understanding Bolt Standards empowers you to specify, inspect, and install fasteners that reliably meet mechanical and environmental demands. By focusing on standards organizations, material grades, thread specifications, and surface treatments, you’ll reduce installation errors, prevent premature failures, and simplify supply chain communication. Next time you draft a purchase order or read a technical drawing, recall these four key facts about Bolt Standards to ensure your projects are built on a foundation of quality and consistency.