As the world becomes increasingly focused on energy efficiency and indoor air quality, Energy Recovery Ventilators (ERVs) are emerging as essential solutions for modern buildings. They strike a balance between sustainability and comfort — reducing energy costs while ensuring a constant flow of clean, fresh air. Whether for homes, offices, or large-scale commercial projects, ERVs are now at the core of smart, sustainable design.

What Is an Energy Recovery Ventilator (ERV)?

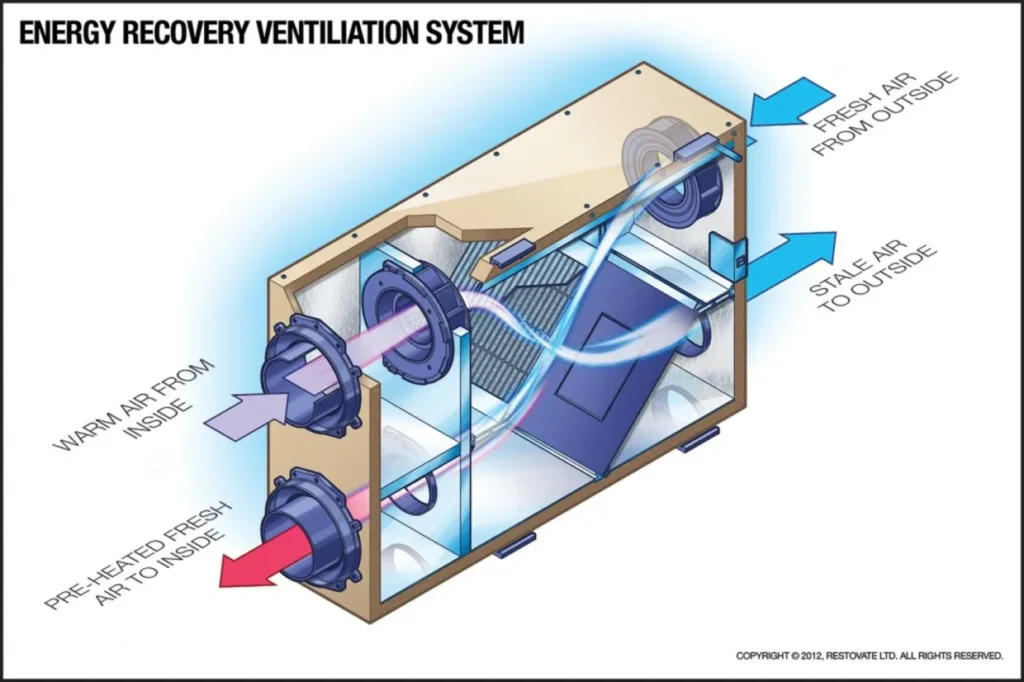

An Energy Recovery Ventilator is a mechanical system that exchanges stale indoor air with fresh outdoor air while recovering energy from the outgoing air stream. In simple terms, it ventilates without wasting energy.

When warm, humid air leaves a building, the ERV captures its heat and moisture to precondition the incoming air. In cold climates, this means incoming air is preheated; in hot climates, it is pre-cooled and dehumidified. The result: better air quality, reduced HVAC load, and significant energy savings.

Why Indoor Air Quality Matters More Than Ever

Indoor environments can harbor pollutants from furniture, cleaning products, cooking, and building materials. With people spending more than 90% of their time indoors, poor air quality directly impacts health, productivity, and comfort.

Traditional ventilation systems bring in outdoor air but often at the expense of higher heating or cooling costs. ERVs solve this problem by allowing fresh air exchange without the energy penalty. They maintain comfortable humidity levels, reduce allergens, and support overall well-being — crucial in both residential and commercial settings.

The Technology Behind Energy Recovery Ventilators

The heart of an ERV is the energy recovery core — a heat and moisture exchanger. As indoor and outdoor air streams pass through this core, thermal energy and moisture transfer between them without direct mixing.

There are two main types of cores:

- Rotary (enthalpy) wheels: These rotate between the exhaust and supply airstreams, transferring both heat and humidity.

- Fixed-plate cores: These use permeable membranes that allow heat and moisture transfer passively.

Modern ERVs integrate advanced control systems, sensors, and smart connectivity features. These allow automatic adjustments based on indoor CO₂ levels, humidity, and occupancy, optimizing both performance and energy efficiency.

Key Benefits of Energy Recovery Ventilators

1. Energy Efficiency

ERVs reduce the load on heating and cooling systems, often cutting HVAC energy use by up to 30%. This leads to lower operating costs and faster payback periods for building owners.

2. Healthier Indoor Air

By constantly refreshing indoor air and managing humidity, ERVs help prevent mold growth, minimize allergens, and maintain a balanced indoor environment.

3. Comfort and Consistency

ERVs maintain stable indoor temperatures and humidity levels, ensuring consistent comfort across seasons and spaces.

4. Sustainability

Reduced energy consumption means lower carbon emissions. For builders and designers, incorporating ERVs supports compliance with green building standards like LEED, BREEAM, and WELL certifications.

5. Quiet, Low-Maintenance Operation

Modern ERVs are engineered for minimal noise and designed with easily replaceable filters, ensuring smooth operation and long service life.

Applications Across Sectors

Energy Recovery Ventilators are versatile and can be adapted to almost any environment:

- Residential Homes: Ensure clean air and comfort for families, particularly in airtight, energy-efficient houses.

- Commercial Buildings: Improve employee productivity and meet ventilation codes without inflating energy costs.

- Healthcare Facilities: Maintain controlled environments essential for patient health.

- Educational Institutions: Provide healthier learning spaces and better air circulation in classrooms.

- Hospitality and Retail: Enhance guest comfort while reducing operational costs.

Integrating ERVs into Modern Building Design

For architects, developers, and facility managers, ERVs represent a future-proof investment. They integrate easily into both new and retrofit projects, complementing HVAC systems for optimal efficiency.

Smart models equipped with digital controls can connect to building management systems (BMS), providing real-time data on airflow, temperature, and energy recovery. This level of monitoring not only simplifies maintenance but also helps in achieving long-term sustainability goals.

Choosing the Right ERV for Your Project

Selecting the right ERV depends on climate, building size, occupancy, and ventilation requirements. Reputable manufacturers offer a wide range of models with different airflow capacities and control features. Key considerations include:

Efficiency ratings and energy recovery effectiveness

- Noise levels and installation flexibility

- Compatibility with existing HVAC systems

- Smart control options for automation and monitoring

Working with trusted industry experts ensures the system is properly sized, installed, and maintained for peak performance.

Conclusion: Smart Ventilation for a Sustainable Future

As energy costs rise and sustainability becomes non-negotiable, Energy Recovery Ventilators are no longer optional — they’re essential. They deliver a powerful combination of energy efficiency, indoor air quality, and comfort, making them the smart choice for modern living and working environments.

From homes to high-performance buildings, ERVs are redefining what it means to live comfortably, breathe clean air, and build responsibly.

Post by: harga ac 1/2 pk acjakarta