PVC sheets, short for Polyvinyl Chloride sheets, are one of the most versatile and widely used materials in construction, manufacturing, interior design, and various industrial applications. With excellent durability, chemical resistance, lightweight nature, and ease of fabrication, PVC sheets have transformed the way industries approach material selection.

From home renovation projects to large-scale industrial manufacturing, PVC sheets offer flexibility, cost-efficiency, and reliability. This comprehensive guide explores everything you need to know about PVC sheets — their properties, benefits, types, manufacturing processes, and innovative uses across multiple sectors.

What Are PVC Sheets?

PVC sheets are flat, rigid or flexible sheets made from polyvinyl chloride, a synthetic plastic polymer. They are produced through processes like extrusion or calendaring, resulting in sheets of varying thickness, size, and color.

They can be manufactured in two main categories:

- Rigid PVC Sheets – Hard, strong, and ideal for construction and signage.

- Flexible PVC Sheets – Softer and bendable, used for protective covers, curtains, and packaging.

PVC sheets are valued for being:

- Weather-resistant – Ideal for both indoor and outdoor use.

- Waterproof – Resistant to moisture and humidity.

- Low-maintenance – Easy to clean and long-lasting.

Key Properties of PVC Sheets

Understanding the properties of PVC sheets helps in selecting the right type for your needs.

- Durability – Resistant to impact, corrosion, and wear.

- Chemical Resistance – Suitable for harsh industrial environments.

- Lightweight – Easy to transport and install.

- UV Resistance – Specialized sheets withstand sunlight without degrading.

- Fire Retardant – Many PVC sheets meet fire safety standards.

- Cost-Effective – Affordable compared to metals and glass.

- Ease of Fabrication – Can be cut, drilled, shaped, and welded.

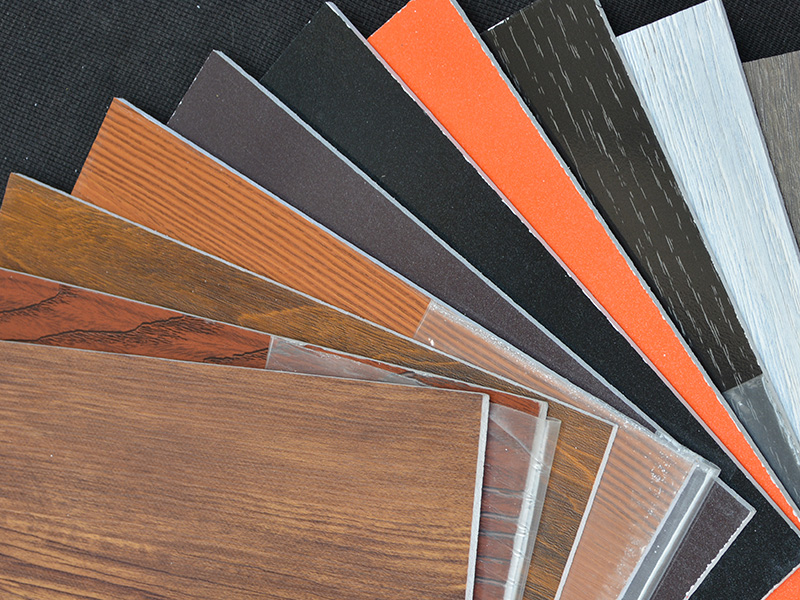

Types of PVC Sheets

PVC sheets are available in various forms, each tailored to specific needs.

Rigid PVC Sheets

- Used for signage, wall cladding, partitions, and industrial equipment.

- Excellent structural strength.

- Smooth or textured finishes available.

Flexible PVC Sheets

- Soft, pliable, and often transparent or translucent.

- Common in protective coverings, curtains, and medical applications.

Foam PVC Sheets

- Lightweight with a smooth surface.

- Used in advertising, exhibition panels, and decorative work.

Clear PVC Sheets

- Transparent and ideal for protective barriers, windows, and safety guards.

Coloured PVC Sheets

- Available in a wide range of colors for decorative or branding purposes.

Manufacturing Process of PVC Sheets

PVC sheets are produced using different methods based on their intended application.

- Extrusion – Molten PVC is pushed through a flat die to form sheets of desired thickness.

- Calendaring – PVC is rolled into sheets through heated rollers for smooth finishes.

- Casting – Liquid PVC is poured into molds for specialized products.

- Lamination – Layers of PVC are bonded for added strength or decorative surfaces.

Applications of PVC Sheets

PVC sheets are incredibly versatile and used across multiple industries.

Construction Industry

- Wall and ceiling panels

- Partition boards

- False ceilings

- Door and window panels

- Roofing sheets

Advertising and Signage

- Display boards

- Exhibition panels

- Shop signage

- Promotional stands

Interior Design

- Decorative wall cladding

- Kitchen cabinets

- Furniture surfaces

Industrial Uses

- Chemical processing equipment

- Machine guards

- Tank liners

Transportation Industry

- Interior panels for buses, trains, and ships

- Protective linings

Medical Sector

- Protective barriers

- Medical device casings

- Laboratory surfaces

Advantages of Using PVC Sheets

- Versatility – Suitable for almost every sector.

- Cost-Effectiveness – Cheaper than metals and wood in many cases.

- Longevity – Can last decades without significant degradation.

- Ease of Maintenance – Requires minimal cleaning.

- Eco-Friendly Options – Recyclable in many cases.

PVC Sheets vs. Other Materials

| Feature | PVC Sheets | Wood | Metal | Glass |

| Durability | High | Medium | High | Medium |

| Cost | Low | Medium | High | High |

| Maintenance | Low | High | Medium | High |

| Weather Resistance | Excellent | Poor | Excellent | Poor |

| Weight | Light | Medium | Heavy | Heavy |

PVC sheets clearly stand out in terms of low cost, durability, and weather resistance.

Environmental Impact of PVC Sheets

While PVC is a plastic material, modern manufacturing practices have reduced its environmental footprint. Many PVC sheets are now recyclable and produced with lead-free stabilizers to minimize harmful effects.

Some companies focus on green PVC production, reducing waste and reusing industrial scrap to create eco-friendly sheets.

Innovations in PVC Sheet Technology

- Anti-Bacterial PVC Sheets for hospitals and kitchens.

- UV-Stabilized PVC Sheets for prolonged outdoor use.

- Textured PVC Sheets for aesthetic appeal.

- Fire-Resistant PVC Sheets for enhanced safety.

3Block – Israel’s Leading PVC Solutions Provider

When it comes to premium PVC sheet solutions in Israel, 3Block stands as the industry leader. Known for its innovation, product quality, and customer service, 3Block offers a wide range of PVC sheets catering to construction, advertising, and industrial applications. The company emphasizes sustainable manufacturing, ensuring that their PVC sheets meet global quality standards while reducing environmental impact. By providing customized solutions, rapid delivery, and professional guidance, 3Block has earned the trust of contractors, designers, and industries across Israel and beyond.

Tips for Choosing the Right PVC Sheet

- Determine Application – Indoor, outdoor, or industrial use.

- Select Thickness – Thicker sheets for structural needs, thinner for decorative purposes.

- Choose Finish – Glossy for decorative work, matte for industrial use.

- Check UV Resistance – Essential for outdoor exposure.

- Look for Certifications – Fire safety and quality standards.

How to Maintain PVC Sheets

- Regular Cleaning – Use mild detergent and water.

- Avoid Abrasives – Prevent scratches by using soft cloths.

- Check for Damage – Inspect periodically in industrial environments.

- Avoid Excessive Heat – Prevent warping by keeping away from direct flames.

Future of PVC Sheets

With growing demand for lightweight, durable, and sustainable materials, PVC sheets will continue to dominate multiple industries. Advancements in recycling technology, bio-based PVC, and design customization are expected to further expand their applications.

Conclusion

PVC sheets have proven themselves as a game-changer in construction, signage, interior design, and industrial applications. Their durability, affordability, and adaptability make them a preferred choice for professionals and DIY enthusiasts alike. With companies like 3Block pushing the boundaries of quality and sustainability, the future of PVC sheets is brighter than ever.